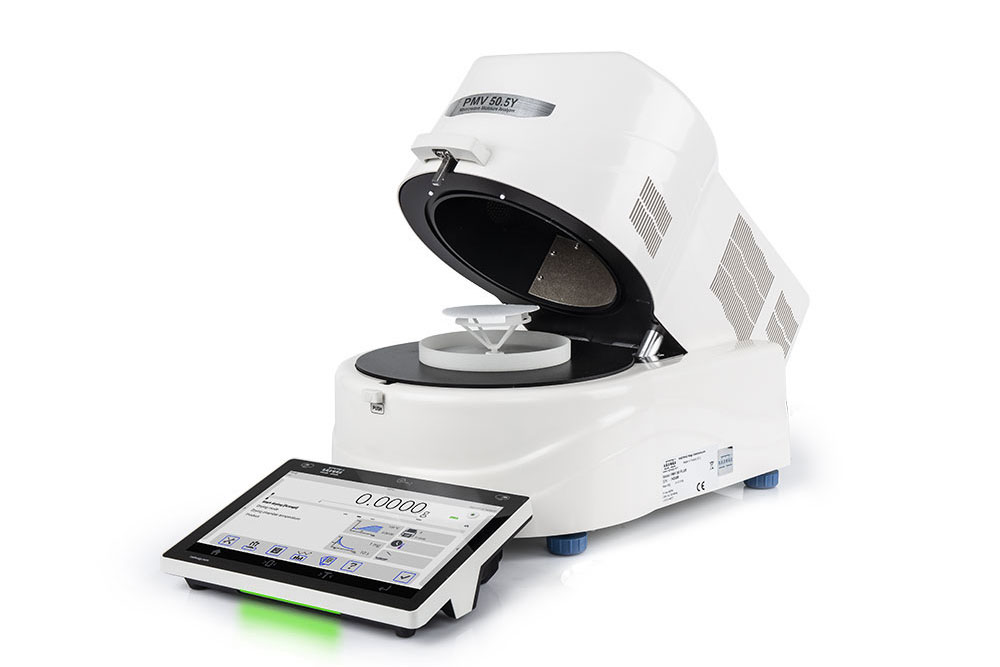

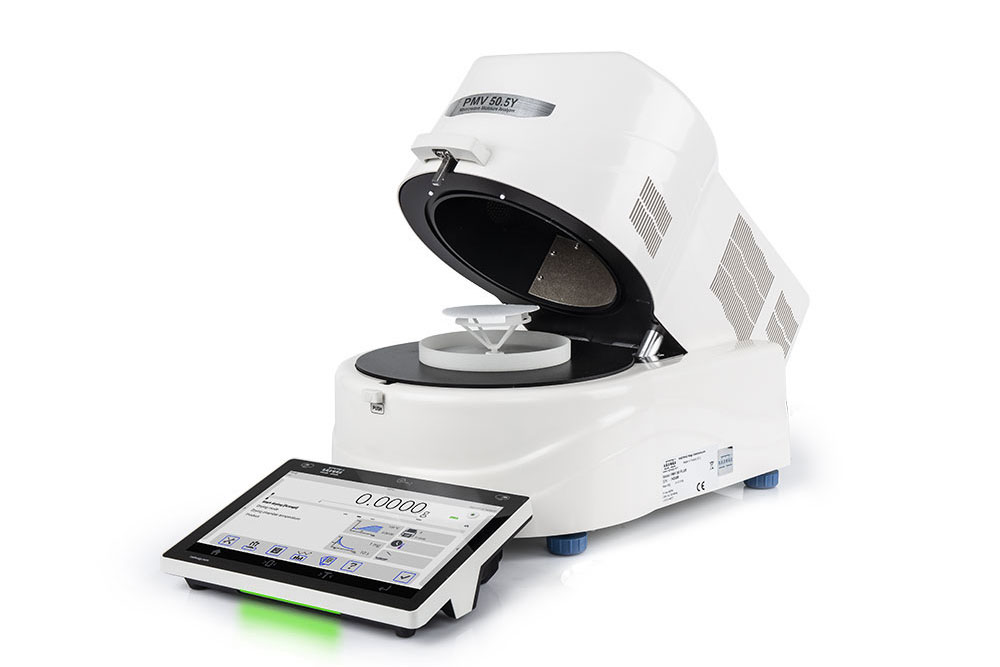

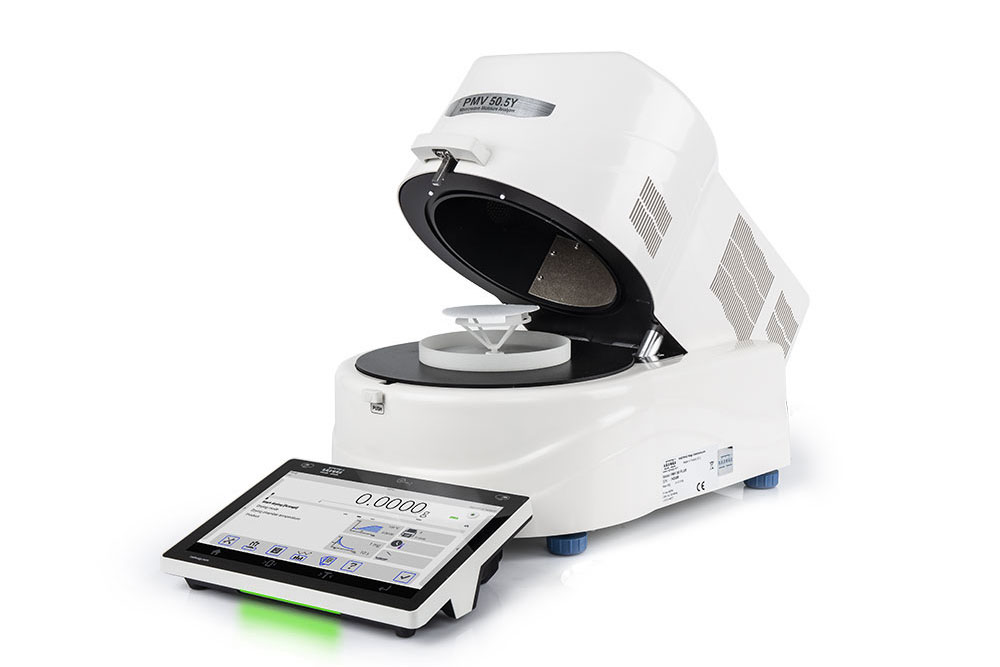

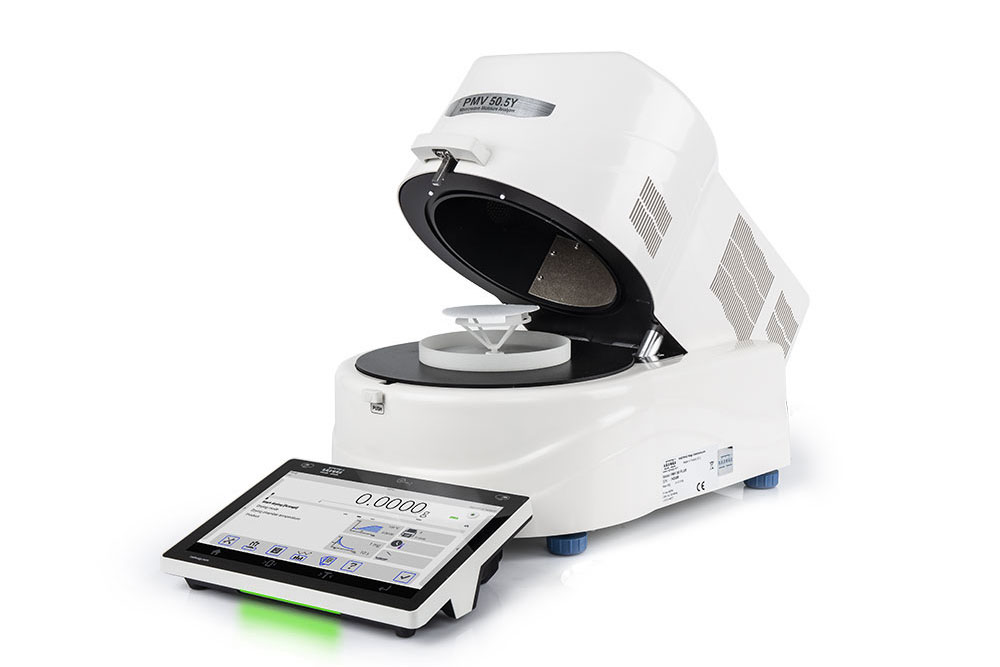

PMV PLUS Moisture Analyzers

- PMV 50.5Y Moisture AnalyzerMax: 50g | d: 0,1mg

Pcs.

We have been manufacturing weighing devices since 1984.

RADWAG UK Limited

16 Macon Court, Herald Drive, Crewe, CW1 6EA

+44 01625 569569

Delivery only on the territory of United Kingdom

Buying from the producer is all about the pros

You always get the latest version of the device and software. We are constantly improving our products.

Technical support from the product developers. Who better to know the answers to your questions? Like our Facebooku profile – stay in touch with us.

A solidly packaged shipment travels only one way – the one to you.

In our permanent offer you will find accessories for our balances and scales, such as cables, weighing pans and power supplies, as well as all spare parts. And we carry out legalization and periodic inspections in our laboratory.

You buy a product developed and manufactured in Europe – you get a device with a certain standard of compliance.

Overview

PMV 50.5Y Moisture Analyzer

The PMV 50.5Y

microwave moisture analyzer can be successfully used wherever materials containing large amounts of water are dried. These materials are, for example, dairy products, fish, meat, fruit products, syrups, creams or liquid resin.

The sample is placed in the drying chamber on a glass fibre filter. At the bottom of the chamber there is one end of the waveguide from where the microwaves are emitted. Upon process start, microwaves are equally distributed on the filter’s surface and dry the sample. The moisture content is determined on the basis of the mass loss obtained during drying.

A respective drying program is selected depending on sample mass and its chemical composition. The average duration of this process depends on the type and mass of used substance, and takes 1 to 10 minutes. In contrast, drying using the traditional halogen moisture analyzer takes 5 to 40 minutes.

The PMV 50.5Y microwave moisture analyzer is equipped with a temperature sensor and enables to monitor device power in order to prevent exceeding the boiling point during the process. A preset microwave power is displayed on the indicator throughout the drying procedure.

The PMV 50.5Y’s main features:

- intended for drying of samples containing significant amount of moisture (up to 100%),

- ultra-short drying time when compared to traditional moisture analyzers and standard drying methods,

- microwave-based solution,

- uniform heating of entire sample’s surface,

- complex database of drying programs,

- finish mode: manual, automatic, time-defined, user-defined,

- advanced reports, time and statistical graphs,

- easy operation due to a touch screen.

For each purchase of the PMV 50.5Y moisture analyzer the customer is supplied with:

- 60 glass fibre filters of ø90 mm,

- a sample of sodium chloride 10% ± 0,5% to determine correctness of the operation at the workstation,

- a service concerning determination of drying parameters for five customer-selected samples carried out by RADWAG employee.

The results obtained using the moisture analyzer (the final result of the drying process):

% M – the mass loss in %; displays the mass change recorded during the drying process, expressed as a percentage,

% D – the dry mass obtained during the drying process, expressed as a percentage; the result is the portion of the sample that remains on the weighing pan after the moisture has evaporated,

% R – the ratio of moisture content to dry mass, obtained during the drying process, expressed as a percentage; the result is the portion of the sample that evaporated during the drying process,

g – the sample mass after drying.

* All trademarks and registered trademarks are the property of their respective owners.

Terminal 5Y in Microwave Moisture Analyzer

With the 5Y terminal, microwave moisture analyzer PMV gain new capabilities and functionalities, such as:

- 10-inch display,

- Digital Weighing Auditor (DWA),

- uncompromised user verification,

- Ambient Light,

- hotspot,

- RFID*,

- Live Note text notes,

- voice commands for the device,

- measurement history within the Handy Library,

- widgets.

Modbus TCP/IP

* RFID ISO/IEC 14443 Type A, 13,56 MHz